Promise For Best Quality

Promise For Best Quality

CASE CARBURISING STEELS

The idea behind using Case hardening steels is to have the same steel with two different properties for the outer surface and core.

Case hardened steel is usually formed by diffusing carbon and/or nitrogen into the outer layer of the steel at high temperature. The carbon combines with the steel to make it nearly glass-like in its hardness. The core of the metal stays soft. This gives you a piece of metal that you cannot cut with a saw, but also will not shatter.

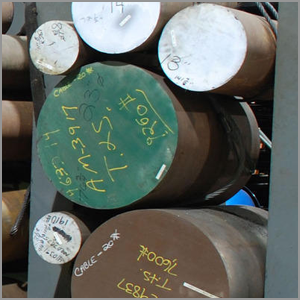

CASE CARBURISING STEELS GALLERY

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| En-36C | Min | 0.12 | 0.30 | 0.10 | 3.00 | 0.60 | 0.10 | Max | Max | |

| Max | 0.18 | 0.06 | 0.35 | 3.75 | 1.10 | 0.25 | 0.015 | 0.02 |

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| 17 CrNiM06 | Min | 0.14 | 0.40 | 0.15 | 1.40 | 1.50 | 0.25 | Max | Max | |

| Max | 0.19 | 0.60 | 0.40 | 1.70 | 1.80 | 0.35 | 0.015 | 0.02 |

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| SAE8620 | Min | 0.18 | 0.70 | 0.15 | 0.4 | 0.4 | 0.15 | Max | Max | |

| Max | 0.23 | 0.90 | 0.35 | 0.7 | 0.6 | 0.25 | 0.015 | 0.02 |

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| 20MnCr5 | Min | 0.17 | 1.1 | 0.15 | Max | Max | ||||

| Max | 0.22 | 1.4 | 0.4 | 0.015 | 0.02 |

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| DIN 20 Cr Ni 4 | Min | 0.19 | 0.95 | 0.20 | 0.90 | 1.05 | Max | Max | 0.20 | |

| Max | 0.21 | 1.05 | 0.30 | 1.20 | 1.15 | 0.015 | 0.02 | 0.25 |

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| EN 353 | Min | 0.20 | 0.50 | 0.35 | 1.00 | 0.75 | 0.08 | Max | Max | |

| Max | Max | 1.00 | Max | 1.50 | 1.25 | 0.15 | 0.015 | 0.02 |

| Grade | % | C | Mn | Si | Ni | Cr | Mo | S | P | AI |

|---|---|---|---|---|---|---|---|---|---|---|

| EN- 354 | Min | Max | 0.50 | Max | 1.50 | 0.75 | 0.10 | Max | Max | |

| Max | 0.20 | 1.00 | 0.35 | 2.00 | 1.25 | 0.20 | 0.015 | 0.02 |

Application :

DTH hammers, Automobile pistons, Couplings, Castings, Gears, Worm Shafts, Button Bits, Gudgeon pins, Sprocket, Front Axle wheel, Gear shaft, Crown wheels, Swing lever and Pressure rings etc.

Copyright © 2017. all rights reserved.